The challenges of X-ray image analysis and the value of training

25 October 2021

By Sara Bracceschi, Head of Consulting and Services for Customs at the Center for Adaptive Security Research and Applications (CASRA)The implementation of X-ray machines to support security screening was introduced approximately 50 years ago to accelerate the process of baggage inspection. Equipment was then developed to enable the non-intrusive inspection of vehicles, containers and trains.

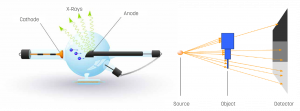

Today’s X-ray systems produce a stream of electromagnetic radiation that interacts with an anode in an X-ray tube within the X-ray machine itself. The X-rays generated in the tube are then directed towards the object to be examined, producing an image (see Image 1).

Different types of X-ray machines exist on the market. They are usually classified as conventional or high energy, depending on the doses of X-rays applied. Conventional X-ray machines are smaller and less powerful X-ray systems, primarily used for airport and cargo screening. Vehicle inspection requires bigger and more powerful X-ray machines which are high-energy systems whose X-ray doses are about one order of magnitude higher than conventional X-rays.

The basics of X-ray systems: colours and density

Officers tasked with image analysis and interpretation of X-ray images should acquire a certain knowledge of the basics of X-ray systems in so far as an understanding of these fundamental elements facilitates the X-ray screening task and ultimately enhances detection performance.

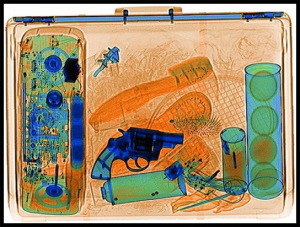

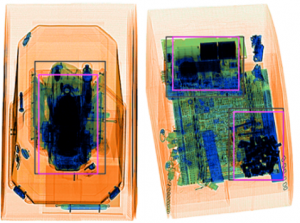

First of all, it is important to know that an X-ray image is genuinely black and white. The term greyscale image is also used. This is actually how all people usually conceptualize X-ray images, as they tend to think of the black and white X-ray images they saw at their doctor’s office. Machines used for the detection of items show objects in different colours to facilitate the recognition of items. In order to obtain coloured X-ray images, dual-energy imaging technology (high and low energy beams) is required. It enables the machine to analyse the atomic composition of the various materials present. A specific colour is then applied to each different atomic composition (see Image 2).

Organic materials are depicted in orange shades and metals in blue, while inorganic and mixed materials appear in green. But there are some exceptions to the rule if, for example, a composition is not 100% clear, such as in the case of a mixture.

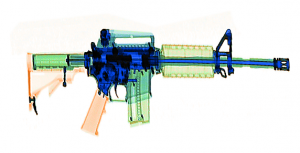

Zinc alloys may, for example, appear green, as in Image 3. Similarly, different types of material that overlap may also be depicted in green.

When an object is X-rayed, some of the X-rays are absorbed by the object, whereas other X-rays pass straight through it. It is therefore the density and thickness of the materials that affect how easily X-rays pass through objects. The lower the density of a material, the more transparent the material is to X-rays, and the lighter and clearer the object will appear in the X-ray image. On the other hand, the denser and thicker an object is, the darker the item in the image will look and the more challenging the identification of objects and potential anomalies will be.

If the X-ray cannot penetrate an item, a dark blue to black colour appears, also known as dark alarm, meaning that the material is so dense that the X-rays could not penetrate it to an acceptable degree (see Image 5). In such cases, it is usually recommended either to repeat the scan from a different angle if possible or to proceed to a manual inspection.

It is worth mentioning that the exact colouring of the materials may vary slightly from one system manufacturer to another, but the underlying principles remain the same.

X-ray image analysis and interpretation: basic factors to be considered

Despite the advances in technology, the actual decision as to whether an X-ray image of a bag or a lorry contains a prohibited item or an anomaly is taken by a human operator, an X-ray screener.[1] In recent years, the focus has been placed on how to enhance operator capacities, as errors in X-ray image screening can lead to severe consequences.

Vehicle inspection, in particular, is an extremely challenging task. It requires analysing the substantial amount of data collected in a single X-ray image within only a few minutes. The identification of prohibited articles becomes even more complicated when dealing with proportionally small threat items, such as a weapon, and even more so when the weapon has been decomposed into parts purposely concealed in different vehicle compartments or among cargo. When it comes to concealment methods, ever changing modi operandi add another layer of difficulty to an already complex undertaking.

Two factors must be considered to enhance man-machine system performance: the selection and the training of X-ray screeners.

Research on the X-ray security screening of passengers at airports has shown that not every individual has the potential to become a good X-ray screener. Specific visual information processing abilities, such as mental rotation, figure-ground segregation and visual search of specific patterns, are very important for the correct interpretation of X-ray images.

Training is inevitably a key consideration. First, all X-ray screeners need to be aware of which items/products are allowed and which ones are not; second, they must know what those items/products look like, both in real life and in an X-ray image. Research on object recognition and visual cognition has taught us that shapes other than or not similar to the ones stored in our visual memory are difficult to recognize or not recognized at all.

Many factors influence the capacity to analyse and interpret X-ray images, such as the viewpoint of an object, the superposition of an object by other objects and the complexity of the image itself.

The identification of a weapon will be difficult if the object is showing from a certain angle (see Image 6), or is mixed with other goods, especially if those are superimposed. An empty container or homogeneous cargo do not present the same level of difficulty as, for instance, heterogeneous cargo.

A by-product of X-ray systems: geometric magnification and distortion

Another challenge with X-ray image interpretation relates to geometric magnification and distortion, which are natural side-effects of X-ray systems.

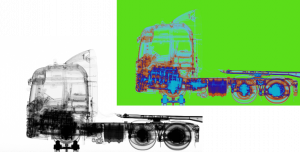

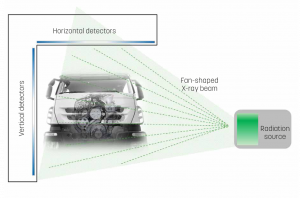

X-rays travel in straight lines. An X-ray source generates a beam of X-rays; one of them will be the central ray of the beam and the others the peripheral rays. As the beam exits the X-ray tube, it will diverge, while the centre point (central ray) of the beam will not suffer from any divergence. There are two types of X-ray beams: fan-shaped and cone-shaped, with fan-shaped being the most prevalent. A traditional fan-shaped beam emits a “fan type” X-ray and is detected by a linear detector array system. Because of the beam shape, this system allows for the whole of a vehicle to be scanned without leaving any dead angle (see Image 7). Additionally, because the intensity of the beam is greater in the centre, it guarantees that even the denser objects in the middle of a lorry can be scanned and hence appear in the X-ray image generated.

However, because of the beam shape itself, the structures that the beam hits first will appear magnified in relation to those which are further away from the source and closer to the detector.

In addition to this magnifying effect, due to the angle at which the beam hits the objects and structures, the ones that are closer to the beam source will shift upwards in the X-ray image, so that ultimately we can see both sides of the object or vehicle scanned.

Understanding these two phenomena enhances the X-ray screeners’ ability to identify objects but also allows them to distinguish where the anomaly is located in real life, which is fundamental for the final step of the vehicle inspection. An X-ray screener who appreciates and is trained on the effects of geometric magnification and distortion will be able to distinguish where the anomaly is positioned, for instance whether certain packages of organic material are located among the merchandise on top of the container floor or inside the container floor, in a hidden compartment, which certainly impacts the decision on whether to clear the vehicle or send it for a physical inspection.

Optimizing performance

The results of different studies have shown that image analysis performance can be improved through training. The objective of the training is to enhance the detection performance of the screener as well as to reduce the reaction time required for recognition to occur. Adaptive computer-based training (CBT) is considered to be a very powerful tool for enabling screeners to achieve and maintain a good X-ray image interpretation capacity. A method is called adaptive if it is able to select an item on the basis of trainee performance at an earlier stage. The term CBT is used for activities in which the computer presents a problem, registers answers and provides feedback.

The use of CBT makes it possible to expose screeners to images of objects that they do not encounter so often in live operation, such as improvised explosive devices, as well as to images of objects from different angles, images showing superimposed objects and images of different complexity levels.[2]

In 2020, CASRA carried out an international cargo study aimed at assessing, among other things, the impact of adaptive CBT on the capacity of trainees to recognize objects accurately and the relevance of X-ray screening selection tests, such as the X-Ray Object Recognition Test (X-Ray ORT). The cargo study demonstrated that substantial improvements in the performance of the screeners can be achieved after approximately 11 hours of training. The number of positive identifications by screeners who participated in the study had increased by 8% on average and the number of false alarms had decreased by 6%.

In terms of the usefulness of the X-Ray ORT, the study showed that such tests can assess the visual information processing capabilities of individuals, independently of the visual knowledge acquired through training and experience. However, it is important to ensure that the objects to be identified in the test are shapes that everyone would be expected to recognize, namely items from everyday life or objects, such as knives and guns, with which individuals have become familiar through cinema and other entertainment media.

It is worth stressing that employees with exceptional visual abilities can learn faster and achieve a higher level of threat detection performance through training. Customs administrations should therefore consider the benefits offered both by CBT systems and the use of a well-designed X-Ray ORT as part of their selection processes.

More information

www.casra.ch

info@casra.ch

[1] Michel, S. et al. (2014), Increasing X-ray image interpretation competency of cargo security screeners, International Journal of Industrial Ergonomics, Vol. 44(4), pp. 551-560.

[2] Michel, S. et al. (2014), Increasing X-ray image interpretation competency of cargo security screeners, International Journal of Industrial Ergonomics, Volume 44(4), pp. 551-560.